When looking to complete a capital improvement project like a community-wide piping system replacement or upgrade, you have several contracting model options. We’ve previously written about why one model—hiring your service or maintenance provider for a large capital improvement project—is often not the best choice. Even among the qualified general and specialty contractors available, you’ll want to consider a number of factors to select the model that’s right for you.

To approach this type of construction project, many of you might naturally assume that you have to obtain three competitive bids. That’s pretty much the convention. Sometimes, though, it pays to defy convention. In fact, you may be able to complete your project in a way that saves time, money, and even frustration.

The competitive bid model

In this model, you first hire a construction manager (CM) to oversee the project. They then help you select an engineer to design your solution. Once the design and specifications are ready, the CM will put the project out to bid through a formal Request For Proposal (RFP) process, soliciting competitive bids from multiple contractors. On occasion, you might hire an engineering firm that can also act as your CM, which means you only need to engage one third party to get started. Either way, you’ll receive a set of plans and specifications from the engineer and the CM will put the project out to bid so that you can shop for the best price.

While on the surface this model makes sense, it has drawbacks.

Namely, you frequently compensate the construction managers and engineers by paying them a percentage of the overall construction project cost. The more expensive the project, the higher their fees—which means that they may not be as concerned as you about marrying safe and effective design with the best possible price.

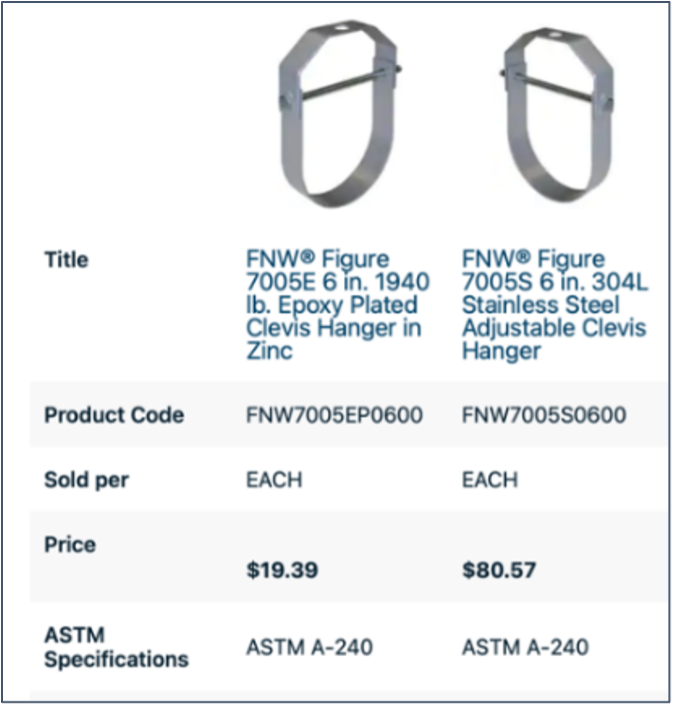

Example of Over-Engineering

We’ve often seen designs that call for stainless steel pipe hangers, which provide structural support for piping systems, where epoxy plated zinc would do just fine at 25% of the cost.

How might the price be inflated? It can happen in a variety of ways. For example, most engineers don’t often design pipe replacement or piping system upgrades, so they simply don’t have the experience to know the best practices or the latest cost-effective trends and techniques for those projects. Whether or not they mean to, they over-engineer their solutions: They may introduce unnecessary complexity in their designs, underestimate or be unaware of common challenges in projects of this type, design to a scope that is beyond the project’s purpose, or specify high-end materials that may not be required for your needs.

In the end, the construction phase of your project will take longer and be more expensive as you deal with change orders that arise from unanticipated issues and pay for unnecessarily expensive materials.

Another drawback of the competitive bid model can occur when the contractors are invited to bid. If they’re new to plumbing and mechanical system renovations or haven’t done them often, they’ll simply provide a proposal for the specified, expensive design.

Even if the contractor sees evidence of over-engineering, they may still bid on what’s specified to stay in good standing with the CM. Believe it or not, there’s inherent conflict that can arise when a contractor tries to act in your best interest by offering to “value-engineer” a solution with lower price alternatives. The designers—whom the CM may represent—may feel put out that a contractor has second-guessed their professional recommendation.

Another reason to be cautious when considering a competitive bid approach is that the competitive bid process can be long and arduous. It takes a while to design the solution, get multiple bids, and then conduct interviews to select a contractor and negotiate the contract. It can take even longer if you ask your CM to invite options for value engineering. In the end, the process can prolong the start of your construction, which costs you valuable time and money—especially if your community is actively combatting frequent leaks.

Defying convention: the design-build model

When weighing the pros and cons of how to approach your project, consider the design-build model for getting the best value and accelerating the start of your project. And remember to look for specialty design-build contractors who are dedicated to community-wide renovations of plumbing and mechanical piping systems.

Design-Build contractors promote an open environment of trust and provide end-to-end services. They are strategic partners who ensure you get the solution you need (nothing more and nothing less) at the best price and within the shortest timeframe.

Differences that can pay—in more ways than one.

One of the first differences you’ll experience in a design-build approach is that you complete the entire project under one contract, with a single point of accountability. Your contractor employs licensed engineers for solution design as well as turnkey construction crews from all the relevant trades—e.g., plumbers, drywallers, painters, carpenters, etc. By having all the experts and craftspeople in-house, a design-build contractor is dedicated to be your advisor, identifying your needs, presenting options, supporting your decisions with expert recommendations, and managing the process end-to-end—from developing plans and specifications, to obtaining permits, to executing the work.

Also, because of the design-build contractor’s full-service operating model, there are far fewer steps in the process, which means you’re likely to get your project off the ground much faster. For example, by selecting a single partner up-front, you can start notifying residents about the project schedule and what they can expect in parallel with the design and permitting process. That’s because you don’t have to wait to put the project out to bid and select a contractor. In fact, it’s in the design-build contractor’s best interest to get the project moving more quickly since they employ field crews who are ready to work. Simply put, project delays cost a design-build contractor money.

In addition to being more efficient, your design-build project can be more cost-effective. Since the design-build contractor is responsible for installing its own designs, there’s never any conflict about scope. In fact, a good design-build contractor will have enough confidence in their design that they’ll offer a “no change order” contract, which means they won’t charge you for unanticipated work that other contractors would charge you for. In all, the number of change orders, unexpected costs, and project delays are reduced significantly.

For example, if your contractor discovers an unanticipated condition during the project—e.g., they open a wall and find something that’s not to code—they can evaluate options and provide you with an immediate recommendation, which helps keep the crews working. In the alternative competitive bid model, the contractor would submit a formal Request For Information (RFI) to the construction manager and await a response from the design team, and then the CM would need your approval for the new charge. In addition to a price increase, this process can cause downtime and scheduling delays.

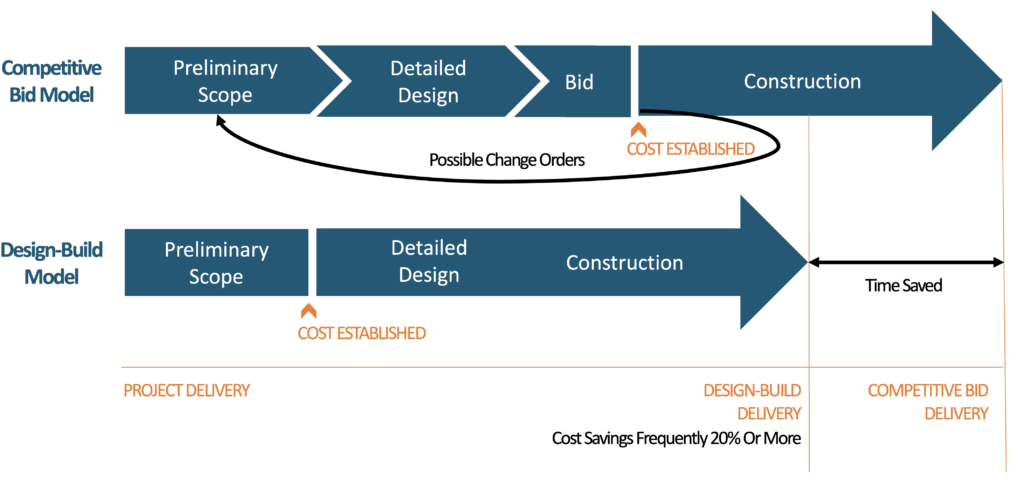

Comparison of Two Contracting Models

Design-build is not as risky or as expensive as you may have expected.

While it may seem counterintuitive to select a contractor without obtaining multiple bids, consider this: First, you can talk with multiple design-build contractors before selecting one. Also, the design-build contractor can help you implement a solution faster with significant cost savings—frequently 20% or more compared with a competitive bid project.It’s worth noting for condominium boards that even when you choose a design-build model, you can still leverage an owner’s representative—which some states, community bylaws, or lenders may require. You’ll still experience time and cost savings compared with a competitive bid model. For example, the owner’s representative charges only a nominal fee to determine that the work is being completed on schedule. Or, if you are financing your project and your bank requires it, your owner’s rep will provide third-party verification of work completed to release funds for paying each invoice.

Also, there’s no inherent tension between the goals and incentives of an independent owner’s representative and design-build contractor the way there may be between a Construction Manager and your contractor. That’s because the owner’s rep is not concerned with project design or scope, only that work is completed as agreed upon in the contract.

The decision is yours. We can help.

As a community association board member or apartment community owner, you’ve likely learned that one of the most challenging parts of kicking off a capital improvement project is deciding how you’ll approach it. The answer determines how much effort you have to put into overseeing the work, how long it will take, and how much it will cost.

It’s natural to lean into conventional approaches like turning to your service or maintenance providers or launching a competitive bid project. Remember though: It can pay to defy convention! At first blush, it may feel risky to go with a design-build contractor, but the benefits can be significant.

For a free consultation on whether a design-build solution could be right for your next plumbing or mechanical system renovation, call us today.

We’d love to hear from you.

Thanks for reading our blog! Contact us any time with questions about Simply Smarter Pipe Replacement for multifamily apartment and condominium communities.