With domestic water pipes (think hot- and cold-water supply piping) in residential buildings across the U.S. reaching the end of their useful life, condominium Boards and multifamily owners/operators are exploring the best options to fix frequent, and sometimes catastrophic, leaks.

Epoxy pipe lining has gained a lot of attention in recent years, with pipe lining providers claiming it’s less invasive and more affordable than pipe replacement.

Unfortunately, there are a lot of myths about the risks and rewards of pursuing epoxy lining as an alternative to a repipe. We’re often asked about epoxy lining by the communities we work with, and it has become obvious that there’s a lack of good information available.

In our experience, epoxy pipe lining for domestic water systems is not an advisable alternative to pipe replacement. We’ve worked with too many clients who’ve had to abandon a pipe lining project and opt for a repipe instead, or who’ve had serious and premature issues with lined pipes.

For this reason, we’re launching a series to help bust the most common myths about epoxy pipe lining. Our goal is to help you understand the benefits and risks so that you can choose the right path to fixing the domestic water piping system in your community.

Epoxy Pipe Lining: The Basics

To kick things off, we’ll answer a few of the most common questions we get about pipe lining.

1. What is epoxy pipe lining?

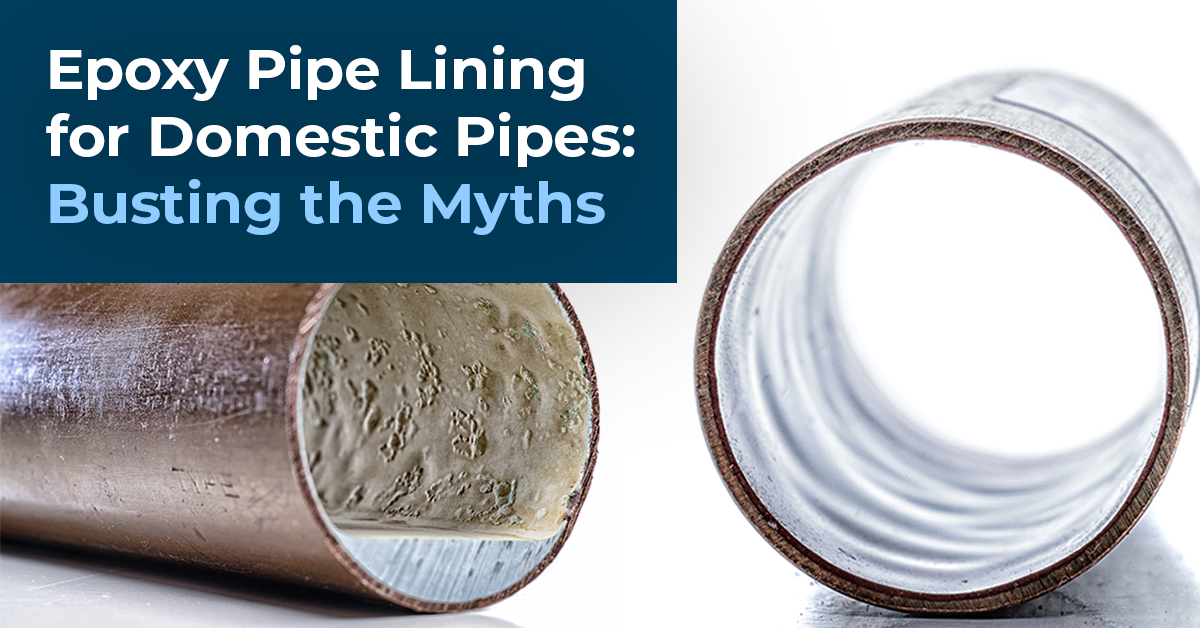

Epoxy is a general term for a variety of plastic resins. Epoxy pipe lining in residential properties is a repair technique that involves cleaning (as necessary) and coating pipes from the inside with epoxy resin to patch holes and stop leaks.

2. How does it work?

The idea behind epoxy lining is to create a “pipe within a pipe,” plugging pinholes, fractures, and cracks, while keeping the community from having to fully replace the system. It doesn’t always work this way, however—and we’ll use this series to dive into some of the things that can go wrong.

3. How is it installed?

For domestic water systems, resin is blown into the pipe from one end.

The installer will drain and dry the pipes, then use an abrasion process like sandblasting to remove corrosion from the interior surface. This smooths the pipe wall so that the lining properly adheres to it. Then, the installer will use forced air to blow liquid epoxy through the pipe until the pipe walls are coated. The epoxy needs several hours to a few days to cure, depending on which resin is used, after which water can be turned back on.

Up Next: Pipe Lining Myths

Over the next several months, we’ll share the most common misconceptions we hear about epoxy pipe lining in domestic water systems and information we’ve gained from our research and experiences working with communities who’ve used it.

Up Next: Pipe Lining Myths

Over the next several months, we’ll share the most common misconceptions we hear about epoxy pipe lining in domestic water systems and information we’ve gained from our research and experiences working with communities who’ve used it.

A few of the misconceptions we’ll explore include:

– The myth that epoxy pipe lining is always less expensive than pipe replacement

– The myth that epoxy pipe lining is always less invasive than pipe replacement

– The myth that epoxy pipe lining is completely safe

Keep an eye on our newsletters for the next post! In the meantime, if you have any questions about pipe replacement, pipe lining, and what’s right for your community, don’t hesitate to reach out for a free consultation.