Pipe lining providers promote their product as a safe alternative to pipe replacement. But while the pipe replacement industry is subject to numerous regulations to protect resident and crew health, pipe lining is still something of a wild west.

If you’re considering lining your domestic piping system, get informed about the risks, considerations, and potential implications for your community’s drinking water before you make your decision. Here are a few things to keep in mind.

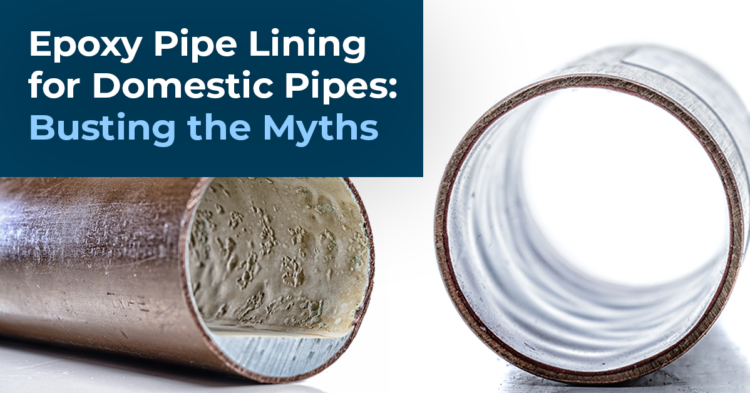

>> This is part of a series exploring myths around epoxy pipe lining for domestic pipes. Learn more about this series by checking out our intro post, Epoxy Pipe Lining for Domestic Pipes: Busting the Myths, and our post about why pipe lining isn’t always less expensive than pipe replacement.

Pipe Lining: Hazmat Risks that Arise in an Unregulated Industry

Pipe replacement providers like SageWater follow a strict regulatory regimen that helps protect both the communities we work in and our crews. One of the most important regulations concerns older buildings, which may have asbestos in the walls. The United States Environmental Protection Agency (US EPA) requires all properties built before 1978 to perform extensive testing for the presence of lead and asbestos-containing materials (ACMs) before disturbing any existing materials. This includes cutting into any wall surface—important when you’re opening walls to access pipes!

What does this look like in action? When a building is of age, we complete hazmat testing before a project begins. If we find hazardous materials, we hire a specialty contractor to create access points under containment with negative air pressure. This ensures the community remains safe during the piping renovation project.

For a pipe lining project, this process looks quite different.

To Test or Not to Test. Unlike repipes, pipe lining projects are considered a repair, so providers aren’t subject to the same regulations or permitting process. Depending on the scope of work, your lining project may require drywall demolition to access certain sections of the pipe (similar to a repipe). But because permits are not required, providers may not complete testing before the job begins. This puts your community at risk.

When you discuss this with your lining contractor, they may say that drywall work is not required, so testing is unnecessary. Proceed with caution!

Many pipe lining projects result in unexpected drywall work. This is because the cleaning process that prepares pipes for lining can often cause blowouts if the host pipe is too brittle or weak. As a result, the contractor must access the broken pipe behind the wall to repair the section so it can accept the liner.

The only way to get to that broken pipe? Cut the drywall! So even if a lining contractor is not expecting to open your walls, in many instances, they can end up needing to anyway.

Extra Headaches for Your Community. While repipe contractors need to follow a set protocol for ACM testing and abatement in advance of a project kickoff, pipe lining providers who can opt not to test may find that they need to open drywall midway through a project. There are two ways they might proceed—and both can cause serious hassles for your community.

If your contractor is above-board, and your property was not already tested for asbestos, your lining project must stop until the testing is performed. This creates a major headache because it means an unplanned water supply disruption for as many days as it takes to complete the testing. Then, if the testing does reveal the presence of ACMs or lead over the limits set by the EPA, proceeding with the project gets complicated. A licensed hazmat remediation contractor must perform wall demolition under EPA- and Occupational Safety and Health Administration (OSHA)–approved containment procedures. Without planning, this can lead to significant work stoppages, increased costs, and considerable disruption to residents.

On the other hand, some lining contractors may not want to deal with this process—so they’ll opt to cut the holes without testing. This creates health risks for their crews and your community and can lead to legal issues. Failure to perform the required testing leaves the building owner or Home Owners Association (HOA) Board of Directors and lining contractor open to significant liability and fines.

Risks Arising from Hot Water Reaction

In addition to risks from a lack of industry regulation, hot water reaction with epoxy pipe lining can introduce potential health risks to your community. The concern comes from long-term exposure of epoxy resin to hot water, which can occur in boiler-fed properties.

Some epoxy lining contractors have National Science Foundation (NSF) approval—a certification to ensure the safety of food, water, and consumer products—for high-temperature hot water interaction. But, perhaps because NSF/ANSI guidance requires testing only up to 140 degrees Fahrenheit (F)1, these providers will typically not warrant the epoxy solution beyond that temperature.

While set points for distribution of domestic hot water temperatures are typically in the 120-to-140-degree (F) range, boilers may cause a spike in temperature above this level, potentially compromising the integrity of the epoxy lining. This is particularly true for properties that routinely boost their boiler temperatures to 150 degrees (F) or higher to prevent and/or kill Legionella bacteria.

With this in mind, be sure to do proper due diligence before deciding if epoxy lining is suitable for a building’s hot water piping. Make sure the liner is NSF certified and that it remains safe and won’t leach harmful levels of epoxy resin chemicals into your drinking supply if it will be exposed over time—even in small sections of lined pipe near water heaters—to temperatures that exceed 140-degrees Fahrenheit.

Research Your Options to Protect Your Community

Epoxy lining is still a relatively new and unregulated industry, so it’s important to get a sense of the risks and pitfalls before you proceed.

Protect your property, community, and residents by researching your options and making an informed decision to repair failing pipes.

*

Throughout our myth busting series, we’ll dive deeper into questions you can ask so that you make an informed decision about what’s right for your community. As part of your research, contact SageWater for a free consultation about the process and costs of a turnkey pipe replacement solution that minimizes disruption for residents.

1 https://d2evkimvhatqav.cloudfront.net/documents/NSF-ANSI_61_watemarked.pdf?v=1594929800 from https://www.nsf.org/knowledge-library/nsf-ansi-standard-61-drinking-water-system-components-health-effects