What Pipe is That?

Piping issues can usually be categorized into two buckets, problems caused by defective products or problems caused by age-related issues. Performing a pipe inspection to assess the type of pipe in your building, knowing when it was installed and how it is aging will help you plan ahead for repairs and avoid costly and catastrophic leaks. When you perform your pipe inspection, here are the types of products and issues you should be looking for:

Defective Products

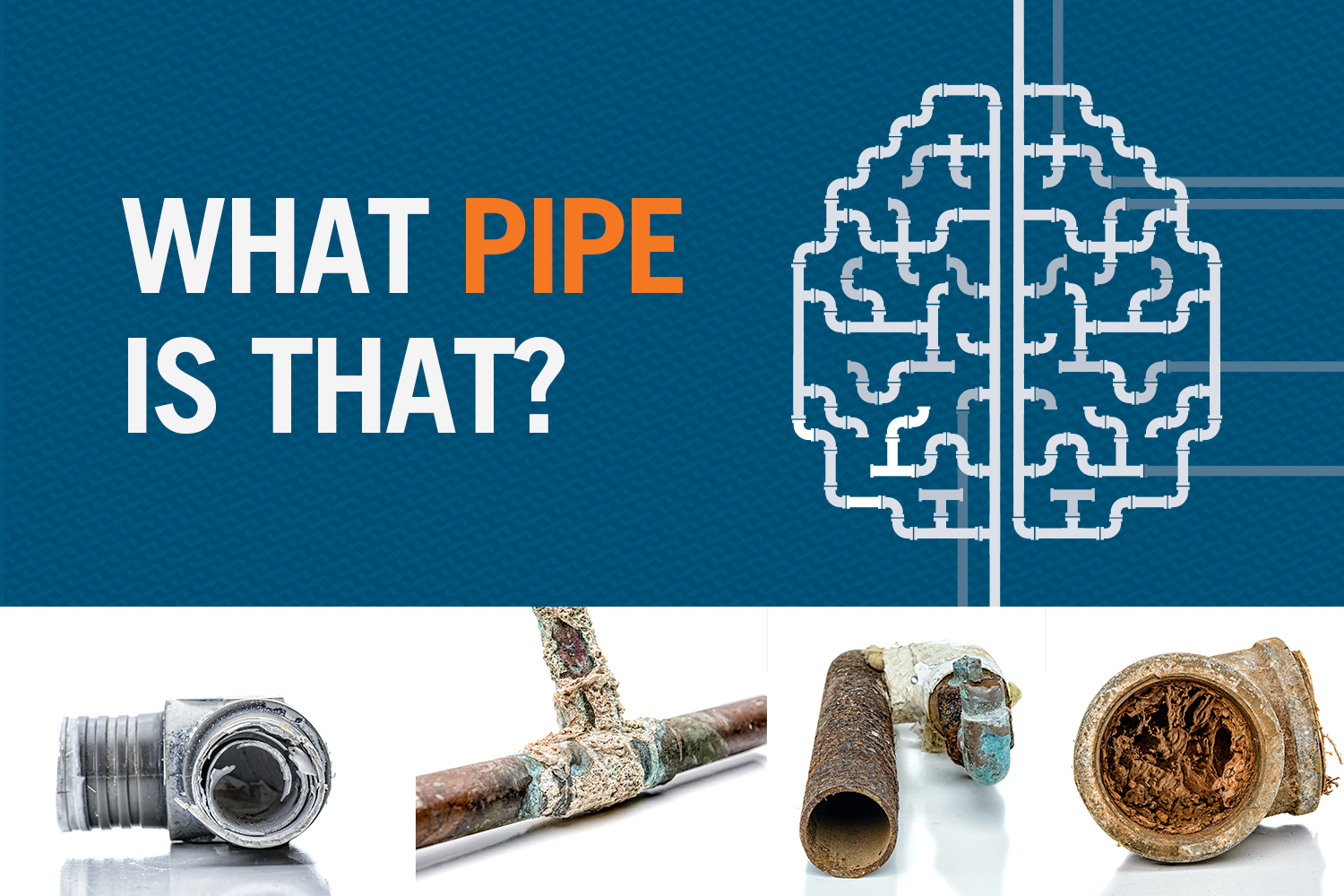

Defective products such as polybutylene or certain yellow brass fitted PEX systems are known to fail prematurely and cause catastrophic leaks and water damage.

Polybutylene or “poly” for short is a plastic resin that was used in the manufacturing of pipes and fittings from 1978-1995. In these pipes, common water additives such as chlorine attack “poly” pipes and fittings, leading to cracking and undetected leaks. These cracks often result in extraordinary property damage like flooding and mold infestation.

Certain PEX pipe systems used connections made with high-zinc yellow brass. These fittings are subject to dezincification (a form of corrosion), which cause stress fracturing and disastrous leaks. During your pipe assessment, look for extensive corrosion specifically at the fitting as an indication there may be a problem.

Age Related Issues

If your building is over 25 years old and you have copper or galvanized piping systems, it’s likely you are experiencing leaks caused by deterioration and corrosion. In potable domestic water systems, aging copper and corroded galvanized piping systems are primary causes of leaks, low water pressure, odors and poor tasting and discolored water.

Another issue to look for is loose or damp insulation. Aging closed-loop systems often experience deterioration of pipe insulation. As a result, condensation can cause these HVAC piping systems to corrode from the pipe’s exterior, creating issues in your hydronic heating and cooling pipes.

In older properties, age-related drain, waste and vent piping issues can be so severe that major blockages and even complete structural failure are not uncommon occurrences. Common symptoms of a corroded and failing cast iron drain, waste, and vent (DWV) piping systems are slow draining water, odors, and back-ups.

As you head into your budget planning season for capital improvement projects, it’s important to plan ahead and perform an assessment of your pipes to avoid any sudden catastrophic disasters. As a building owner, resident or property manager, inspecting your pipes should be part of your regular annual routine to ensure your piping system is in proper working condition and not showing dangerous signs of aging.

Request More Information or a Quote Today: