Innovating Our Solutions and Our Website. As we introduce new solutions to better meet your needs, we’re also rolling out a new and improved website. Thank you for your patience during this time.

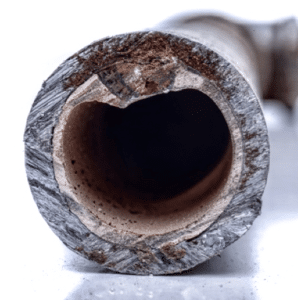

Epoxy Lining is a general term for a variety of different plastic resins used on hot and cold water supply pipes, sprinkler lines, HVAC piping, gas lines and certain drain, waste and vent piping. The National Sanitation Foundation (NSF) and U.S. Environmental Protection Agency (EPA) have certified some epoxy linings for carrying potable drinking water. Epoxy resins are generally not certified as a “structural improvement” to the existing piping system.

Click on the icons below to read more about the concerns and challenges of epoxy pipe lining.

Known Limitations

Hot Water, Hydronic and Commercial Concerns

The commercial application of epoxy and long-term implications of hot water exposure (such as in boiler fed properties) are also causes for concern. While some epoxy lining contractors have NSF approval for high-temperature hot water interaction, these providers will typically not warrant the epoxy solution beyond 140 degrees. While set points for domestic hot water temperatures are typically in the 120 to 140 degree range, boilers may cause a spike in temperature above this level, potentially compromising the integrity of the epoxy lining. This is particularly true for properties that routinely boost their boiler temperatures to 150 degrees or higher to prevent and/or kill Legionella bacteria.14 As such, proper due diligence should take place before deciding if an epoxy lining is suitable for a building’s hot water piping.

In addition, the chemicals added to hydronic piping systems to help maintain the life of the equipment and improve efficiency may or may not be approved to interact with the epoxy resin. Any lining of hydronic systems must be carefully considered and tested before potentially creating an undesirable chemical reaction.

Lack of Exterior Corrosion Protection

At best, epoxy lining may help reduce leaks originating at the interior of the pipe. That’s only half the problem. Exterior corrosion can also be the cause of pipe failures, and epoxy lining does nothing to address this issue. This is particularly problematic on hydronic cooling systems where insulation failures over time have led to condensation on the outside of the pipe, resulting in exterior corrosion. It can also be a problem for cast iron drain, waste and vent piping systems. In the end, an epoxy liner may only be a Band-Aid® to temporarily address the symptoms (leaking pipes) without curing the root cause of pipe deterioration (electrolysis, condensation, etc.)

Potentially Limited Interior Corrosion Prevention

If the installation process isn’t adequate, corrosion can continue between the pipe and the liner, ultimately eating through pipe, the liner, or both. Generally, epoxy is not a structural material, so this presents a potential problem on domestic water supply systems. If lining is too thin, or has holes, or if the pipe was not sufficiently cleaned almost perfectly in the “sand blasting” process, corrosion can potentially eat through the lining causing delamination and leaks that persist. Considering that corrosion is the key driver behind having to perform the renovation in the first place, and lining is often promoted as stopping future corrosion, to what extent is a lining contractor willing to warrant against future corrosion? The biggest consideration with regard to corrosion from the inside of the pipe is uniformity of the applied lining product and most importantly, the thoroughness of the pipe cleaning process. And as explained above, lining will not prevent corrosion on the outside of the pipes from continuing.

Partial System Coverage

This should be a major point of consideration for a prospective buyer of a lining solution. Typically, valves cannot be lined, and if they are, the valves will not work. Depending on the system, some simple fittings such as tee’s, may not be able to be properly lined because of the challenges with air volume going around the corners (both for cleaning the pipe before lining and for blowing in the resin). As such, some lining solutions only cover the straight sections of pipe, leaving fittings and valves uncovered and at risk of further corrosion if not replaced. Likewise, where the lining stops, there is always the risk of water (and corrosion) getting between the lining and the pipe wall, so the more “gaps” in the piping system, the greater the risk. The best way to get “complete” coverage is to repipe the property, removing all the old components and replacing them with new ones.

Not Always Approved For Plastic Pipes

Some epoxy resins have not been approved by the NSF or the International Association of Plumbing and Mechanical Officials (IAPMO) for lining PEX and other plastic supply piping, as the resin requires a rigid surface to coat and adhere to the pipe. The problem with this is that many properties have repaired pinhole leaks in galvanized steel or copper piping systems with PEX or CPVC where sections of metal pipe have already been removed and replaced with a plastic alternative. If, for example, an epoxy vendor is bidding on a project that has had a large number of PEX repairs, they could unknowingly create conditions that fail to meet manufacturers specifications by using epoxy on the PEX portion of the piping system. This means they would be required to either not coat those parts of the system, or replace the plastic pipe with metal pipe before proceeding with the lining job. The risks are that the epoxy may not adhere properly which could lead to delamination and it may not be a compatible material with the plastic.

Lack of Governmental Inspection

Epoxy lined pipes typically are not inspected by any governmental or third party agency. Unlike a repipe that is inspected pursuant to the local government’s approved code, there is a very limited ability to perform third party inspections for epoxy installations without randomly removing sections of pipe. With no one checking on the quality of the installation, buyers must simply trust that their contractor is installing the solution appropriately. Unfortunately, based on observations of real world failures, this is often not the case. As such it is highly recommended that an epoxy-qualified third party inspector be retained to perform random destructive testing throughout performance of the project to ensure the work meets all required standards.15

The ICC-ES (International Code Council – Evaluation Services) is a nonprofit, limited liability company that does technical evaluations of building products, components, methods, and materials. The evaluation process culminates with the issuance of technical reports that, because they directly address the issue of code compliance, are extremely useful to both regulatory agencies and building-product manufacturers. Agencies use evaluation reports to help determine code compliance and enforce building regulations; manufacturers use reports as evidence that their products (and this is especially important if the products are new and innovative) meet code requirements and warrant regulatory approval. 16

Epoxy manufacturers can submit their products to ICC-ES for approval. Upon being certified, those manufacturers can then use the ICC-ES stamp of approval as a credential to promote their material under the claim that it has been evaluated and approved by a third party testing service. However, these approvals come with specific stipulations regarding the use and installation of the product. For example, when addressing epoxy lining of a domestic water piping system, one of the ICC-ES Installation requirements states:

“After drying in accordance with the manufacturer’s instructions, the (insert provider) then reassembles the piping system and hydrostatically pressure tests to 150 psi in the presence of the code official or the official’s designated representative. In the presence of the code official or designated representative, the (insert provider) applicator then conducts a flow test to verify the minimum flow rate to each fixture…”17

Unfortunately, performing a flow test to each and every fixture in a high-rise multifamily community (in the presence of a code official) may simply be too time and labor intensive to be practical and may potentially be skipped in many applications. In this scenario, epoxy installers would be in violation of the very same ICC-ES code that they promote as part of their own credentials, rendering the third party approval invalid.

Challenges with Larger Diameter Pipe

Larger pipes (anything over 2 to 2 ½-inches) require the use of a massive air volume for the blown-in installation process. 3-inch to 4-inch pipes are exceedingly difficult to properly coat with high pressure air, and many epoxy lining companies will not include those larger pipes in their scope of work. If there are large supply mains on the property, repiping may be the only recommended choice.

Epoxy Lining Conclusions

The overwhelming amount of risk associated with epoxy lining, coupled with observations of failed installations and their consequences, has led the authors to conclude that epoxy lining pipes within the building envelope is not a comparable alternative to pipe replacement. Before making an investment decision, it is always advisable for a community to explore all its options, including a repipe, to ensure their property is making the most informed decision possible about fixing its leaking pipes.