Epoxy pipe lining is an umbrella term for a variety of different plastic resins used on hot and cold-water supply pipes, sprinkler lines, HVAC heating and cooling piping, gas lines, and certain drain, waste, and vent piping systems. While the National Sanitation Foundation (NSF) and U.S. Environmental Protection Agency (EPA) have certified some epoxy linings for carrying potable drinking water, epoxy resins are generally not certified as a ‘structural improvement’ to the existing piping system.

And, even though manufacturers’ and installers’ claim that epoxy is a cost-effective and safe alternative to pipe replacement, there are actually numerous risks tied to epoxy pipe lining applications, including health and safety concerns, application limitations, warranty issues, and installation concerns.

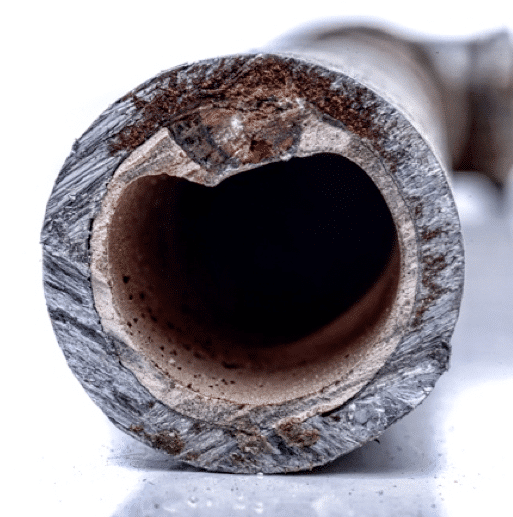

One of the main risks associated with the installation of epoxy is delamination of the resin. After installation, corrosion can develop between the pipe and the liner, causing the liner to become detached (or delaminated). If the lining application is too thin, has holes, or if the pipe was not cleaned properly prior to the application, the delamination process can accelerate considerably.

Delamination carries a number of concerns. First, where delamination occurs, corrosion persists, leading to continued leaks and system failure. However, potentially worse than the leaks, the epoxy can begin to flake off and enter the drinking water supply. In addition, as the delaminated epoxy particles flow downstream, there is an increased risk for blockages as fragments of lining become trapped in the pipe and inhibit water flow.

While epoxy may be marketed as an alternative to pipe replacement, the reality is that it carries a number of risks you simply don’t have with a traditional pipe replacement. And when compared side by side, the costs are typically more comparable than most prospective buyers would think. In addition, buildings that chose to line their pipes rather than replace them are finding that, after delamination, they have no choice but to replace them, essentially paying twice to get their pipes fixed!

For more information on the limitations of epoxy lining your pipes, read our full white paper and for more information on pipe replacement reach out to us.